Our Head Office Plant acquired ISO9001 certification in February 2001, and we are making ongoing quality improvements on this basis. Today, this standard has been revised into the ISO9001: 2015 version. We will adapt to our new system while inspecting our existing quality management system.

When an issue is brought to light through a daily work report and daily inspection report that are submitted each day, the quality improvement committee gathers at the site in question the following day, and while looking at the problematic part, makes an immediate decision on the cause and countermeasures, and takes quick action to resolve it.

The managers at each plant convene a meeting from 7:50am everyday to report on the progress of quality improvement activities and nonconformities from the previous day, discuss countermeasures to be taken, and relay these countermeasures to site managers.

We have implemented the following kinds of initiatives to raise employee motivation.

1.Quality awareness-raising activities through monthly quality reports

2.Human error prevention activities

・Small group work to eliminate careless mistakes

・Thorough work checking (self-checking) and mutual checking (double-checking)

・Producing and applying jigs to make work foolproof

3.Awareness-raising by making self-declarations at the morning assembly

4.Implement reciprocating 5S and QC patrols between plants

High quality standards are demanded from the manufacture of harnesses for industrial robots and medical equipment, the manufacture of various control panels, and from control equipment for the latest specialized power supplies. Reliable inspection results are required as proof that these high standards have been met. Our company engages in the development of automated inspection with the goal of eliminating human errors and variations in worker technical skill and experience. We have commercialized our own automatic inspection device (Cyber Tester®) which has resulted in greater quality, a significant reduction in man-hours, and major cost savings.

We started applying Statistical Process Control (SPC) and Measurement Systems Analysis (MSA) to improve process capability and to comply with ISO-TS 16949 for the management of global suppliers. We are stabilizing processes while quantitatively monitoring changes in the production process and product variations, among other factors.

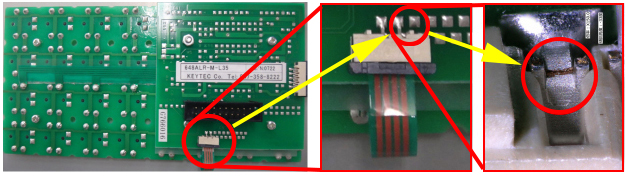

We have introduced the use of a microscope which is effective in discovering soldering cracks and poor crimping that cannot be detected with the naked eye.